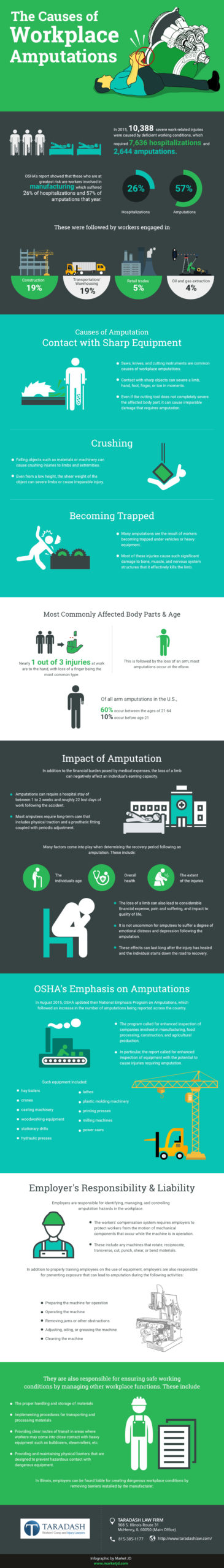

Thousands of people lose limbs, fingers, and toes each year due to workplace injuries. In 2015, 10,388 severe work-related injuries were caused by deficient working conditions. These required 7,636 hospitalizations and 2,644 amputations.

OSHA’s report showed that those who are at greatest risk are workers involved in manufacturing which suffered 26% of hospitalizations and 57% of all amputations that year. These were followed by workers engaged in construction (19%), transportation/warehousing (11%), retail trades (5%), and oil and gas extraction (4%).

(Article continues below Infographic)

______

Causes of Amputation

Contact with Sharp Equipment – Saws, knives, and cutting instruments are common causes of workplace amputations. Contact with sharp objects can severe a limb, hand, foot, finger, or toe in moments. Even if the cutting tool does not completely severe the affected body part, it can cause irreparable damage that requires amputation.

Crushing – Falling objects such as materials or machinery can cause crushing injuries to limbs and extremities. Even from a low height, the sheer weight of the object can severe limbs or cause irreparable injury.

Becoming Trapped – Many amputations are the result of workers becoming trapped under vehicles or heavy equipment. Most of these injuries do not cause immediate amputation, however, they do cause such significant damage to bone, muscle, and nervous system structures that it effectively kills the limb.

Most Commonly Affected Body Parts & Age

Partial hand amputation (loss of a finger) is the most common type of injury. This is not surprising given the fact that nearly 1/3 of all injuries at work are to the hand.

The loss of a finger or entire hand is followed by the loss of an arm. Most arm amputations, occur at the elbow. Of all arm amputations in the United States, 60% occur between the ages of 21-64, while only 10% occur before age 21.

Impact of Amputation

The amputation of a limb such as a leg, foot, arm, or hand can have severe consequences for the individual. In addition to the financial burden posed by medical expenses, the loss of a limb can negatively affect an individual’s earning capacity.

Amputations can require a hospital stay of between one to two weeks and roughly 22 lost days of work following the accident. However, this does not mean that the injury has fully healed once the injured worker leaves the hospital. Indeed, many factors come into play when determining the recovery period following an amputation. These include the individual’s age, overall health, and the extent of the injuries. Indeed, most amputees require long-term care that includes physical traction and a prosthetic fitting coupled with periodic adjustment. These fittings and adjustments will last throughout an individual’s lifetime.

As such, the loss of a limb can also lead to considerable financial expense, pain and suffering, and impact to quality of life. It is not uncommon for amputees to suffer a degree of emotional distress and depression following the amputation. These effects can last long after the injury has healed and the individual starts down the road to recovery.

OSHA’s Emphasis on Amputations

In August 2015, OSHA updated their National Emphasis Program on Amputations. This followed an increase in the number of amputations being reported across the country. The program called for enhanced inspection of companies involved in manufacturing, food processing, construction, and agricultural production.

In particular, the report called for enhanced inspection of equipment with the potential to cause injuries requiring amputation. Such equipment included hay bailers, cranes, casting machinery, woodworking equipment, stationary drills, hydraulic presses, lathes, plastic molding machinery, printing presses, milling machines, and power saws.

Employer’s Responsibility & Liability

Employers are responsible for identifying, managing, and controlling amputation hazards in the workplace. McHenry workers’ compensation lawyers and their clients can rely on laws and a workers’ compensation system that require employers to protect workers from the motion of mechanical components that occur while the machine is in operation. These include any machines that rotate, reciprocate, transverse, cut, punch, shear, or bend materials.

In addition to properly training employees on the use of equipment, employers are also responsible for preventing exposure that can lead to amputation during the following activities:

- Preparing the machine for operation

- Operating the machine

- Removing jams or other obstructions

- Adjusting, oiling, or greasing the machine

- Cleaning the machine

They are also responsible for ensuring safe working conditions by managing other workplace functions. These include the proper handling and storage of materials, implementing procedures for transporting and processing materials, as well as providing clear routes of transit in areas where workers may come into close contact with heavy equipment such as bulldozers, steamrollers, etc.

Employers are required to provide and maintain physical barriers that are designed to prevent hazardous contact with dangerous equipment. In Illinois, employers can be found liable for creating dangerous workplace conditions by removing barriers installed by the manufacturer.